Search

Future Excavated

India’s infrastructure boom is unearthing a new era of smart, sustainable, and connected hydraulic excavators powering tomorrow’s construction landscape.

Cummins Launches HELM™ Engine Platforms at Bharat Mobility

Introduces the innovative Cummins HELM™ engine platforms in India.

Komatsu’s New WA700-8 Wheel Loader

Komatsu has introduced its WA700-8 wheel loader, featuring advanced engine technology and an updated 12-cubic-yard bucket that enables it to fill a 70-tonne haul truck in just four passes.

Earthmovers Surge Ahead

Earthmoving equipment sales soar 21 per cent in FY24, dominating the Indian construction equipment market.

Eco-Diggers!

Backhoe loaders are at the forefront of the sustainable construction movement, revolutionising the industry with groundbreaking energy-efficient technologies.

OEMs are evaluating multiple options of adopting alternate fuel.â€

BKR Prasad – General Manager, Marketing, Tata Hitachi Construction Equipment

JCB aims to cut carbon footprint with fuel efficiency plan

Deepak Shetty, CEO & Managing Director, JCB India

Powering Progress

The article explores the reasons behind the increasing usage of diesel engines in construction equipment, their impact on performance and efficiency, and the technological advancements shaping the future of construction machinery.

Terex’s Concrete Mixers with Hydrogen Engine

In a groundbreaking move, Terex is poised to offer Cummins' X15H hydrogen internal combustion engine as an alternative for its Terex Advance Commander Series of front-discharge concrete mixer trucks.

Valvoline, Eicher Trucks extend partnership

Valvolineâ„¢ announced the extension of its exclusive partnership for service fill and after-sales with Eicher Trucks and Buses.

Eicher drives modernisation in CV industry with future-ready Uptime Services

The company is expanding dealership network and scripting a customer centred experience

Volvo and Eicher products acknowledged at the 14th Apollo CE Awards

VE Commercial Vehicles - A Volvo Group and Eicher Motors Joint Venture have won six prestigious awards for their modern range of vehicles in India, all of which are backed by smart industry-leading solutions at the recently concluded Apollo CV awards 2023.

Volvo and Eicher products acknowledged at the 14th Apollo CE Awards

Volvo 9600 Seater and Sleeper Coach wins Coach of the Year (Premium Category)

Manitou: Spearheading the growth

Manitou has a wide range of telehandlers for every segment, for every application.

Volvo CE India showcases biodiesel blends for CE range

Volvo CE India has announced that its customers across the country will have access to select biodiesel blends to run their Volvo machines.

Premium lubrication solutions for successful mining operations

As a core industry, the mining sector plays a significant role ininfluencing the economic growth of our resource-rich country.

Hamm | HC Series: Advanced Engine Technology for Earthworks

Since August 2021, Hamm has supplied new compactor models from the HC series to the Indian market. The machines, weighing 11t, are available with or without a drum drive.

Poised for growth

With the mining segment getting government support in a big way, the truck and tipper segment will witness growing demand in the days to come.

Hariharan: Customers are cautious in trying out alternative fuels

Anand Hariharan, Head – Product Development, Tata Hitachi Construction Machinery, speaks on challenges the CE industry would face by moving to complete electric.

The world is transitioning towards sustainable business practices.

Our emphasis has always been to keep the customer foremost in our mind. We have therefore, laid special emphasis on customer-friendly products and solutions that are easy to adapt to and help in enhancing usability and serviceability.

Hamm | HC series: Advanced engine technology for earthworks

Since August 2021, Hamm has supplied new compactor models from the HC series to the Indian market. The machines, weighing 11t, are available with or without a drum drive.

Tech Drives Backhoes

Backhoe loader manufacturers are leveraging digital technology by integrating Big Data and the Internet of Things in their models.

Eicher’s heavy-duty truck range focuses heavily on uptime

VE Commercial vehicles is known to offer a robust product portfolio in the heavy-duty range, starting from 18.5T to 55T and Pro 3019, Pro 6028T, Pro 6028TM, Pro 6048 and 8035XM are some of our best performing models in this segment.

The worst is over for the CV industry

In 2008, two leading players, Volvo Group and Eicher Motors, in the commercial vehicle business joined hands with a common vision of driving modernisation in the commercial transport business in India.

Backhoe Loaders Bouncing Back

In the current market conditions, the customer focus will be on equipment with better productivity and cost saving. Backhoe loader with its multi-utility advantage and competitive price will drive the demand in the current market scenario.

Mahindra launches Sarpanch Plus tractor series in Maharashtrasolution

Mahindra’s Farm Equipment Sector recently introduced its new Sarpanch Plus range of tractors in Maharashtra, the 575 Sarpanch Plus, an upgrade of its popular 575 Sarpanch. The new series offers models spanning multiple HP-points in the 30 HP (22.37kW) to 50 HP (37.28kW) category.

Mahindra launches Sarpanch Plus tractor series in Maharashtra

Mahindra’s Farm Equipment Sector recently introduced its new Sarpanch Plus range of tractors in Maharashtra, the 575 Sarpanch Plus, an upgrade of its popular 575 Sarpanch

Eicher Launches BS-VI Range

VE Commercial Vehicles (VECV) unveiled its entire BS-VI range of trucks and buses across 4.9-55 T tagged with Eicher's BS-VI solution, EUTECH6.

Eicher launches its BS-VI solution

VE Commercial Vehicles Limited, (VECV) unveiled its entire BS-VI range of trucks and buses across 4.9-55T tagged with Eicher?s innovative BSVI solution - EUTECH6.

Compliance Challenges

Embracing the next level emission regulations is expected to be tough for the engine and equipment OEMs considering technology upgradations and need for adequate skill development among the users.

Bigger Digger

Optimum utilisation of excavators is of utmost importance for the economic operation of the machine. All hydraulic excavator OEMs have introduced matching technologies for the optimum performance of their machines.

Rolls-Royce supplies first MTU Tier 4 final oil & gas engines in China

Rolls-Royce has received its first order in China for Series 4000 MTU engines fulfilling EPA Tier 4 final emissions regulations.

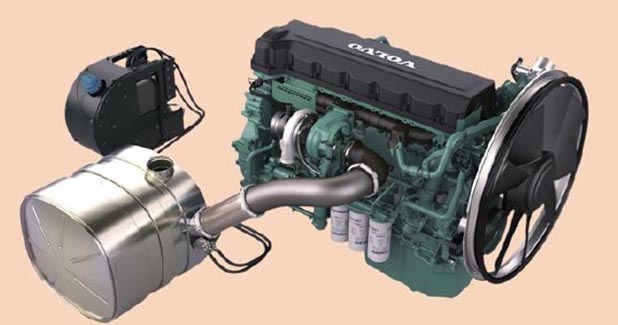

Engines of growth

In spite of the stringent emission norms and green initiatives, diesel power is projected to remain the dominant technology for heavy machinery operations. This is because of its unique combination of power, performance, efficiency, reliability, durability and availability.

SDLG unveils Tier-IV Final wheel loader at BICES 2017

SDLG launched one of its most environmentally friendly wheel loaders at the 2017 Beijing International Construction and Machinery Exhibition & Seminar (BICES) in China. The SDLG L959F is the company?s newest Tier-IV final wheel loader, and it serves as a reflection of the company?s commitment to more environmentally friendly engine technology powering its construction equipment. The new loader will help customers meet the strictest emission standards in regions around the world.

Lubricants market in India is getting more lucrative

The expected robust demand for construction equipment and machinery is going to generate a concomitant demand for industrial and construction machinery lubricants in India. Akhil Jha, Chief Technology Officer, Shell Lubricants India, explains more on the new trends and product innovations in lubricants.

Kohler Engines to exhibit innovations at Demopark 2017

Kohler will be showcasing its products at Demopark, which will take place in Eisenach, Germany, during June 11 to 13. The product portfolio on display will comprise its award winning innovative diesel engines, including vertical and horizontal gasoline engines, as well as its recently introduced trifuel engines, which highlights Kohler?s great effort in alternative fuels.

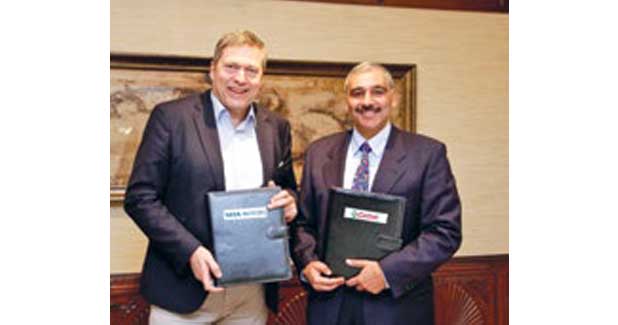

Tata Motors, Castrol in pact for CV oils

Tata Motors and Castrol signed a three-year strategic partnership agreement for supply of commercial vehicle (CV) oils to Tata Motors globally. The agreement will cover over 50 markets including SAARC and ASEAN region, Middle East, Africa, Russia and Latin America.

Tata Motors, Castrol in pact for CV oils

Tata Motors and Castrol signed a three-year strategic partnership agreement for supply of commercial vehicle (CV) oils to Tata Motors globally. The agreement will cover over 50 markets including SAARC and ASEAN region, Middle East, Africa, Russia and Latin America.

Clean Diesel Engines

To begin with, Off Highway Research, a part of KHL group in their half yearly report that in terms of percentage growth, India is expected to be the most buoyant major market in the near-term, with 21 per cent growth forecast this year

Lubricants: Smooth Sailing Ahead

With the government moving fast to meet the latest emission norms and OEMs making further improvement in design, the lubricants industry is set to witness a major revolution in product innovation.

LiuGong is planning to set up its financing arm and the process is on

The growth potential largely depends on the opportunities coming up in the market and is driven by the announcement of different projects by the government.

Powered for the long haul

Commercial vehicle OEMs - domestic and global - have pumped in investments, augmented capacities, launched global platform strategies, enhanced touch points, and stressed on soft solutions to suit the demands of emerging markets.

We plan to launch a new cabin for our existing range

We are developing multiple new platforms in terms of products and customer engagement initiatives and given our scale, we are in the best position to efficiently integrate our products

Cat 320D Series 2 Hydraulic Excavator

Building on the solid performance of its 320D predecessor, the new 320D Series 2 hydraulic excavator is an exceptionally reliable, highly productive machine that lowers operating costs through reduced fuel consumption and simplified routine maintenance. The 320D Series 2 machine features a new engine, powerful hydraulic system, durable main structures and a refined operator station.

Achieving Cost Efficiency

Cost efficiency is not only achieved through cleaner engines, but also through optimising the man-machine interface with a variety of machine control technologies, 'correcting' the usage patterns, and packaging solutions that take care of clients' business needs around project costs.

VECV launches pro-series

Unleashing a huge new wave in trucks, Volvo Eicher Commercial Vehicles (VECV) has recently unveiled the Pro-Series ? 11 trucks in the 5 to 49 tonne categories.Over three million engineering hours, 77 lakh km of testing, 3,200 new parts/sub-assemblies and over 50,000 hours of engine test development

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com